UBTECH robots transform production at Zeekr factory

Zeekr's smart factory in Ningbo, Zhejiang province, has set a new benchmark with its dozens of UBTECH humanoid robots, using "Swarm Intelligence" technology to perform the world's first large-scale, multi-task collaborative training in an industrial setting.

These robots seamlessly coordinate in key production areas, including the final assembly workshop, SPS instrument zone, quality inspection section, and door assembly area. Their versatility in complex manufacturing environments is exhibited through tasks such as high-load material handling, intelligent sorting, precision assembly, and quality control.

In sorting operations, the robots employ cross-domain visual perception and intelligent decision-making to track and sort dynamic objects in real time. For collaborative material transport, a multi-robot control system enables precise trajectory planning, load recognition, and adaptive control, significantly improving efficiency in handling large and heavy components.

Precision assembly tasks further highlight the robots' dexterity. Equipped with five-fingered hands, they can adjust their grip strength and positioning to handle delicate soft-film components without damage or misalignment, demonstrating exceptional adaptability in industrial applications.

According to Zhao Chunlin, vice president of Zeekr Technology Group, this deployment marks a significant leap in AI-powered manufacturing. AI has become an engine that is empowering Zeekr in R&D, production, supply chain, quality control, and operations.

As a national-level 5G factory and one of Zhejiang's first "Future Factories", Zeekr's Ningbo plant is pushing the boundaries of intelligent manufacturing by integrating AI, 5G, and industrial big data.

Humanoid robots transport goods in the Zeekr factory. [Photo/Ningbo Daily]

Ningbo seabird project seeks international volunteers

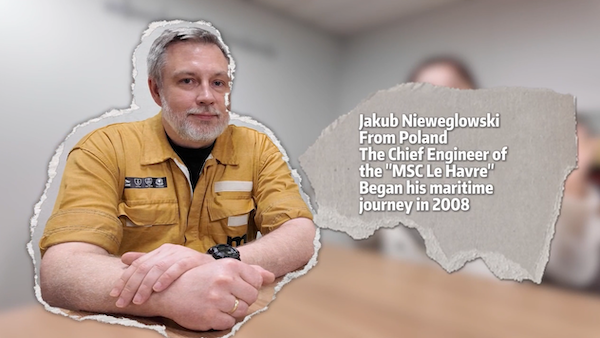

Ningbo seabird project seeks international volunteers  Jakub's journey: From shipyard to sea

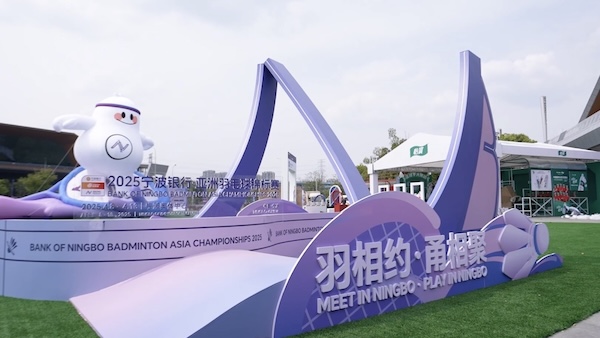

Jakub's journey: From shipyard to sea  Badminton Asia COO applauds Ningbo

Badminton Asia COO applauds Ningbo